Umshini Wokugaya Umshini Wokugaya Umshini kaRaymond

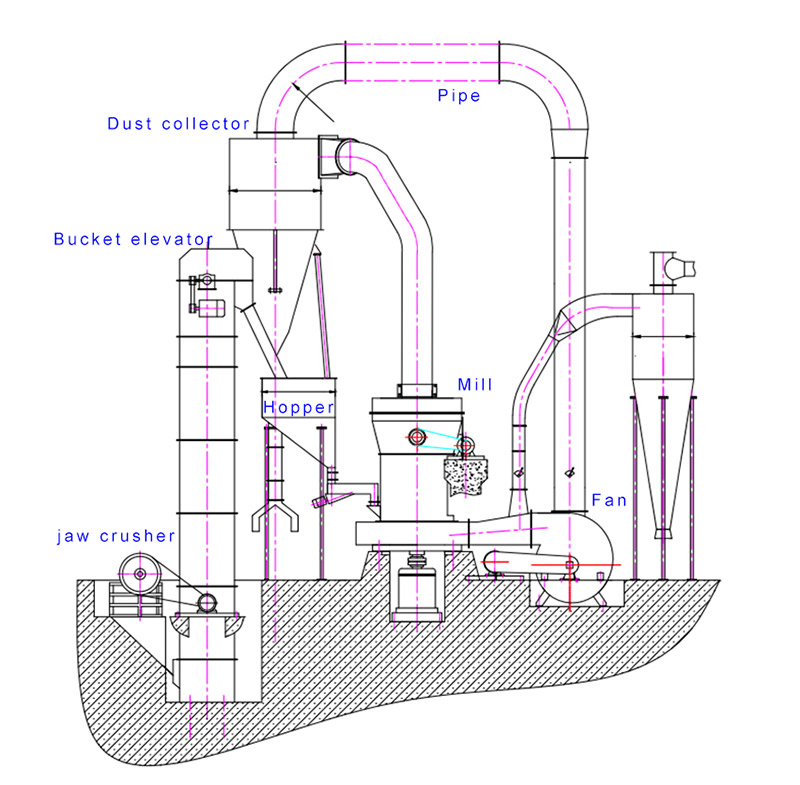

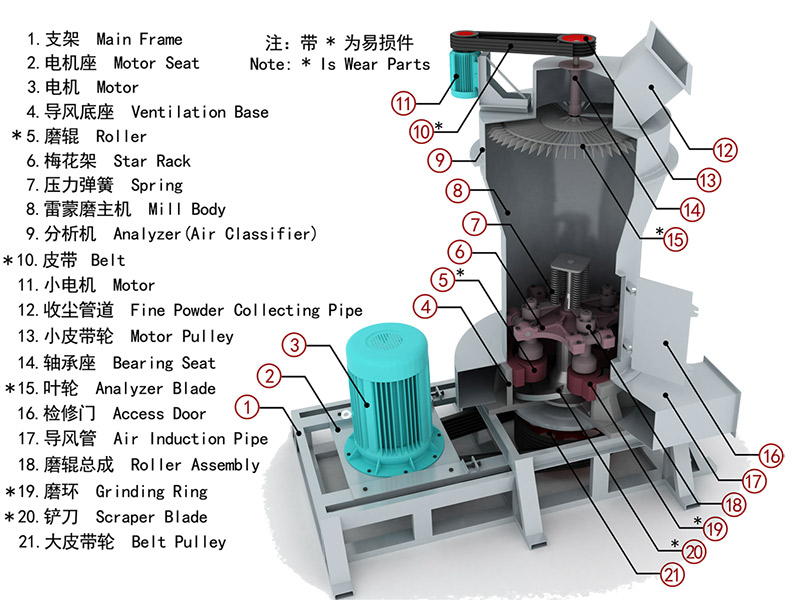

Umshini wokugaya uRaymond uwuhlelo oluhlanganisa i-crusher, ukuphakela, nokugaya, ukuhlukanisa.Isakhiwo somshini wokugaya ikakhulukazi sakhiwe umshini omkhulu, i-analyzer, fan, isihlukanisi se-cyclone esiphelile, isihlukanisi se-micro powder cyclone kanye ne-air duct.Injini enkulu yakhiwe ngohlaka, i-air inlet volute, i-blade, i-grinding roller, indandatho yokugaya kanye nekhava.Ngaphandle kwalokho, izingxenye eziyinhloko zokugaya i-raymond i-roller neringi kanye nefosholo lokuphakamisa.Zonke zenziwe nge-high manganese alloy egqokekayo ephezulu i-Mn13Cr2.

Isimiso Sokusebenza

Okokuqala, izinto ezingavuthiwe zichotshozwa nge-crusher yomhlathi kuze kufike kusayizi odingekayo wesigayo sikaRaymond, esiphakanyiselwa phezulu ku-hopper.Okwesibili, impahla eluhlaza ingena egumbini lokugaya ngesiphakeli esidlidlizayo ngenani elilinganayo.Okwesithathu, impahla eluhlaza ephakanyiswe ifosholo igaywa ibe yimpushana phakathi kweringi nerola.Okwesine, impushana iqhunyiswa kumqoqi wesishingishane ngokusebenzisa i-classifier, ezoqoqwa nge-valve yokukhipha.Impushana engadingeki, engakwazi ukudlula ku-classifier, izophinde igaywe ibe yimpushana edingekayo.

Ukucaciswa

| Imodeli | Inombolo yerola | Roller Usayizi (mm) | Usayizi Wokondla (mm) | Usayizi Wokuphuma (mm) | Amandla (T) | Amandla Ezimoto (kw) | Isisindo (t) |

| 3R1510 | 3 | 150*100 | 15 | 0.2-0.044 | 0.3-1.2 | 7.5 | 2 |

| 3R2115 | 3 | 210*150 | 15 | 0.2-0.044 | 0.4-1.6 | 15 | 3.6 |

| 3R2615 | 3 | 260*150 | 20 | 0.2-0.044 | 0.8-2.5 | 18.5 | 4.2 |

| 3R2715 | 3 | 270*150 | 20 | 0.2-0.044 | 0.9-2.8 | 22 | 4.8 |

| 3R2715 | 3 | 300*150 | 20 | 0.2-0.044 | 1.2-3.5 | 30 | 5.3 |

| 4R3016 | 4 | 300*160 | 20 | 0.2-0.044 | 1.2-4 | 30 | 8.5 |

| 4R3216 | 4 | 320*160 | 25 | 0.2-0.044 | 1.8-4.5 | 37 | 15 |

| 5R4121 | 5 | 410*210 | 30 | 0.2-0.044 | 3-9.5 | 75 | 24 |

Raymond Mill Izinzuzo

1.Okukhiphayo okuphezulu.Okukhiphayo kwesigayo sethu saseRaymond kukhuphuka ngo-10% -20% uma kuqhathaniswa ngaphansi kwesimo samandla esifanayo.

2. Ibanga elikhulu lokucoleka kokugcina.Usayizi womkhiqizo wokugcina uphakathi kuka-0.2mm -0.044mm (40-400mesh).

3. Ukulawula uthuli okuhle.Umshini wethu uhlangabezana nemfuneko yezinga likazwelonke lokulahla uthuli.

4. Kulula ukusebenza.Lonke uhlelo luhlanganiswe ezinye izinhlelo ezizimele, futhi ukuhlangana phakathi kwezinhlelo kuhle.

5. Ukubekwa uphawu okuhle kakhulu.Idivayisi egqitshwayo isebenzisa uphawu olunezigaba eziningi lohlobo olubekwe phezulu, olunokusebenza okuhle kokuvala.